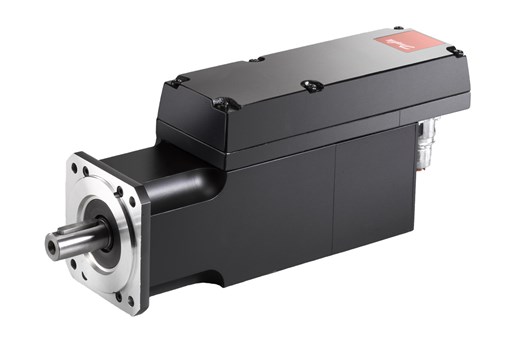

VLT® DriveMotor FCM 300

Danfoss VLT® DriveMotor FCM 300 Consisting of a motor and VLT drive, this unit is the ideal solution for simple control applications.

VLT® DriveMotor FCM 300

|

The VLT® DriveMotor FCM 300 has reached the Limited phase of its lifecycle and is no longer in active production. The FCM 300 induction motor is no longer available as a spare part. Limited supplies of frequency converters and accessories are available as spare parts. |

Limited: A drive entering the Limited phase has limited service options. Only a limited amount of spare parts, maintenance and repair services are available as long as materials can be obtained. Danfoss cannot guarantee availability of the lifecycle services for technical reasons or within reasonable costs. Only existing service contracts with our customers will be supported.

Succesor VLT® DriveMotor FCP 106

|

The VLT® DriveMotor FCP 106 is the best alternative, designed for motor mount, focused on pump- and fan applications in HVAC segment but also fitting simple conveyor applications. It is not a 1:1 replacement for FCM 300. The motor is not included and the drive comes with different physical dimensions, wiring and parameters, but it is the successor at application level. Please remember to order the FCP 106 Motor Adapter Plate as an accessory for motor mounting; or the FCP 106 Wall Mounting Plate for wall mounting. Supply voltages and power range 3 x 380-480 V...0.55-7.5 kW |

Full flexibility in system design

For full flexibility in motor type, system design and energy efficiency, attach the standalone VLT® DriveMotor FCP 106 to your choice of induction motor or permanent magnet motor.

Installation is simple due to the integrated cooling system and an individually adjustable motor adapter plate. Alternatively, mount the VLT® DriveMotor FCP 106 close to the motor using the wall mount adapter plate.

The need for cabinets and long motor cables are eliminated enabling you to save costs however your system design looks.

Built-in features for smooth and efficient pump, fan and conveyor operation make this drive easy to integrate and commission for these dedicated applications.

Supply voltages and power range

- 3 x 380-480 V...0.55-7.5 kW

Features and benefits

The drive operates reliably in wet, dirty and corrosive environments due to the IP66/Type 4X Outdoor enclosure and PCB protection.

Energy is saved and drive lifetime is extended due to the sleep mode.

High overload capability supports applications with a high starting torque.

The VLT® Memory Module MCM 101 facilitates helpful implementation of factory settings for OEM and machine builders, speeds up commissioning and simplifies drive updates.

Installation and maintenance costs are reduced since external components, such as control and monitoring devices, are no longer required.

Share this product

Similar Products

Services we provide

We Manufacture Customized LT Panels, Energy Auditing, Harmonics Study & Analysis and are channel Partners with Danfoss, Omron & Rittal Power.

Customized Panel Design & LV and MV Panel boards

We have a state of the art panel manufacturing facilities. We provide VFD, Soft starter application solution & manufacture of customized electrical panels such as Drive panels, PLC panel, Machine control panel, PCC, MCC, APFC etc.

Sales, Support & Training for Danfoss power electronics product

We are the proud and official Danfoss Sales and Servcice Partners and provide Support and Services for Danfoss based applications and Projects.

Sales, Support & Training for OMRON Automation product

We provide Sales, Servcice and Support for Omron Automation Products like PLC, HMI, Servo Motor/Drive, Sensor, Controller, Powersupply, Relay, Safety Product, Robotics, Vision sensor etc.

Energy Management System

We provide major industries Energy Mangement, Energy Audit, Demand Monitoring and Control, Energy Billing System, Prepaid Metering Solutions & Motor Protection Systems.

Harmonic Survey

An Harmonics Survey is designed to promote maximum operating reliability of the facility electrical system along with the sensitive electronic equipment such as telecommunication equipment, motor systems (e.g. VFD-s) while providing for a safe working environment.

On Site Tech Support, AMC and Repairing of Drives of any make

24/7 and 365 Days addresal of any problem or query is what we belive in when we talk about support. We offer Tech Support Onsite as well as Off site on projects we have worked upon, or some project we are consulting at.

_7881393925ef2f3dedbec4.jpg)

_7675439475ef2f292210d6.jpg)